- read

- Daniele Paganelli

The transition between α quartz and β quartz at 575°C involves a large volume expansion and causes a discontinuity in the thermal expansion n of ceramics.

Industrial processes take into account this effect in the cooling phase, as residual stresses can develop between fast-cooling and slow-cooling portions of a ceramic products. Rapidly shrinking quartz crystals immersed in the ceramic matrix can rupture or detach, seeding microcracks and increasing brittleness.

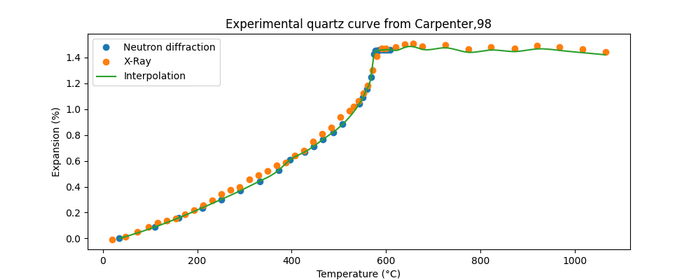

Daniele Paganelli developed the Quantification of Transient Quartz (QTQ) method for calculating an apparent volumetric concentration of quartz from the optical dilatometric expansion curve, which is related to the actual quantity of quartz contained in the ceramic body. The numerical technique decomposes the thermal expansion curve as the weighted sum of the characteristic non-linear thermal expansion of the pure quartz from the overall quadratic interpolation of ceramic body expansion between 475°C and 675°C.

Optical Dilatometer measurements on reference samples of pure quartz sand mixed with alumina powder are run in order to verify the method. The use of a contactless measurement technique is mandated by the incoherent nature of the powders. QTQ is then applied to a raw ceramic body with known pre-firing quartz content, which is fired in the Optical Dilatometer and then measured again to verify the effect of prolonged quartz exposure to the glassy phases on its apparent transient quantity.

The QTQ method is now available in Ceramics Genome, the online database and modeling platform developed by ELS. Ceramics Genome directly connects to MDF instruments, backs up all their data and offers an easy web interface for browsing results, plotting and executing powerful mathematical models.

This case study shortly presents the four QTQ models:

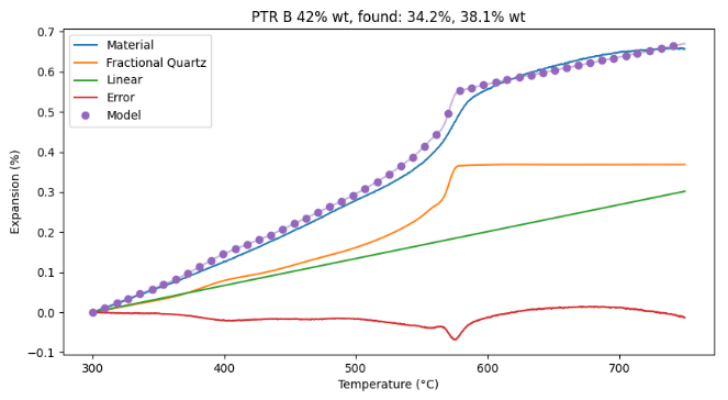

- Post-Transition Removal (PTR), a simple linear fitting method weighting the pure quartz expansion curve in the measurement – fast but underestimates low quartz contents.

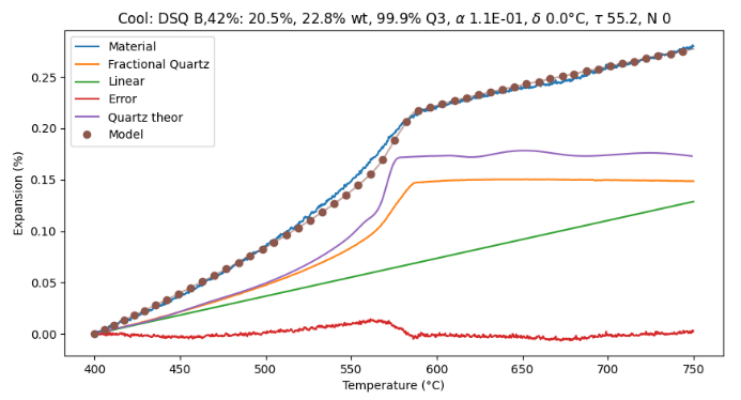

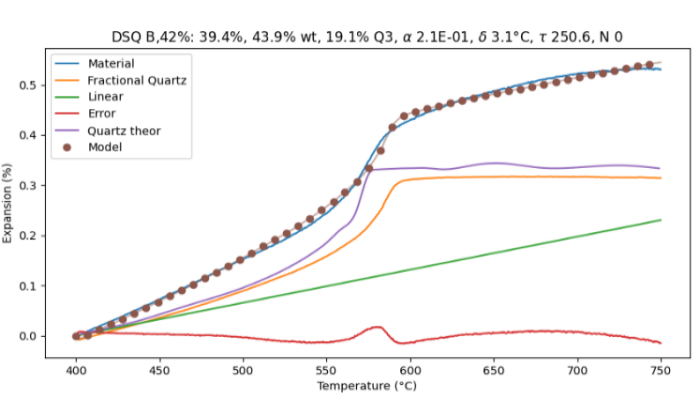

- Delayed Smoothing of Quartz (DSQ), a more heavily mathematical method involving the estimation of the smoothing of the pure quartz curve caused by variable quartz granulometry.

- Linear Combination of Granulometries (LCG), combining measured expansion curves of pressed quartz powders of 2 or 3 different granulometries.

- DSQ and LCG can be combined together, obtaining the DSCG (Delayed Smoothing of Combined Granulometries), where the curve to be smoothed is no longer that of pure quartz, but a combination of curves of different granulometries that is itself optimized in the process.

This case study applies PTR and DSCG on a porcelain tile body that was tested before and after firing, extracting its quartz content. A previous XRD analysis showed 42% of quartz in the green body.

Post transition removal consists in performing a linear regression between 620-720°C, right after the quartz transition but largely before any glass transition, obtaining the α coefficient of the material excluding the quartz contribution. This linear component of the expansion curve is shown as the green line of the following plot. The model (violet) adds the fractional quartz curve (yellow), which is fitted in order to better reproduce the real measurement (blue).

The PTR estimation is 38% of quartz (34% volumetric), against 42% found by the XRD. The Delayed Smoothing of Combined Granulometries (DSCG) finds a better fit and result, with 43.9% of quartz (39.4% volumetric). The linear combination of 2 granulometries assings 19% to the thinner fraction.

After firing the apparent quartz content drops to 23% (20% volumetric) with 100% attributed to the thinner component.